When the car is over 100k miles, running hot or low oil for a while, the oil cooler plastic coolant pipe would break and leaks slowly under pressure (when the car turned of after reaching operating temperature). The leaks appear to be from the water pump but it’s not, it’s dripping from behind the alternator which is directly below the oil cooler pipe and water pump. Before we assumed that the water pump is leaking, remove the driver side fan (disconnect the electrical wiring), remove the timing belt cover and run the engine to see if the water pump squirting out coolant.

The leaks could be from this black plastic pipe here.

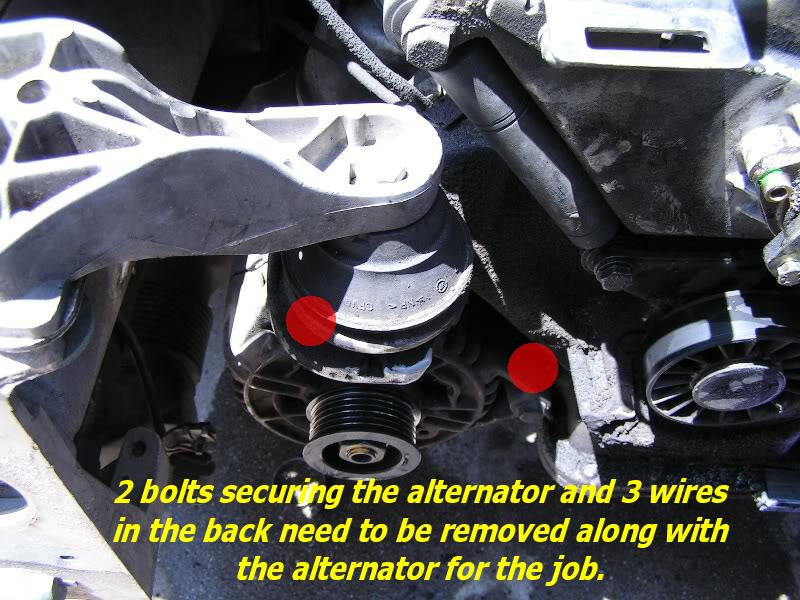

If we’re doing this job without the waterpump or timing belt, we only need to remove the front end, air filter housing, alternator, drain the coolant. Alternator must come out.

Remove front end of 32V A8

We can check the leaks to see if it’s from the water pump by removing the timing belt cover and run the engine to see. On the D2, it may be necessary to remove the fan out of the housing and make sure the electrical cable is DISCONNECTED.

The part is less than $13.00 at the dealer, but the removing and installing the oil cooler is tedious and required some patient and skills.

We removed the timing belt covers to do this. The best is to replace this when changing the timing belt or water pump.

Remove the alternator (www.audipages.com) has good information for this replacement. Drain the oil, remove the oil filter, filter cover, air filter housing, alternator.

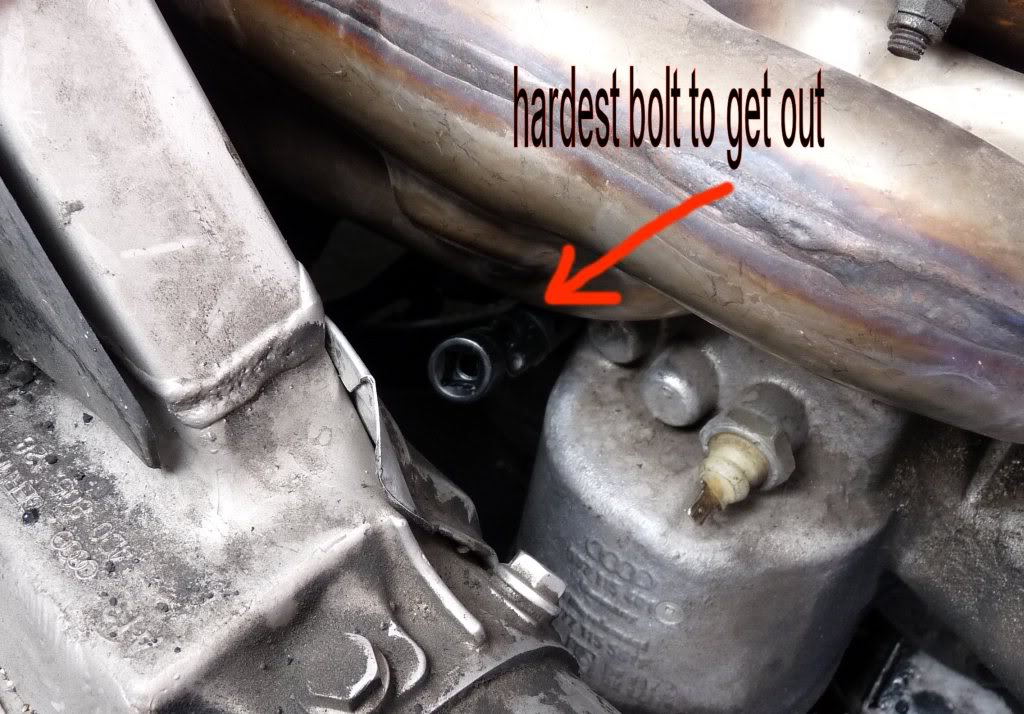

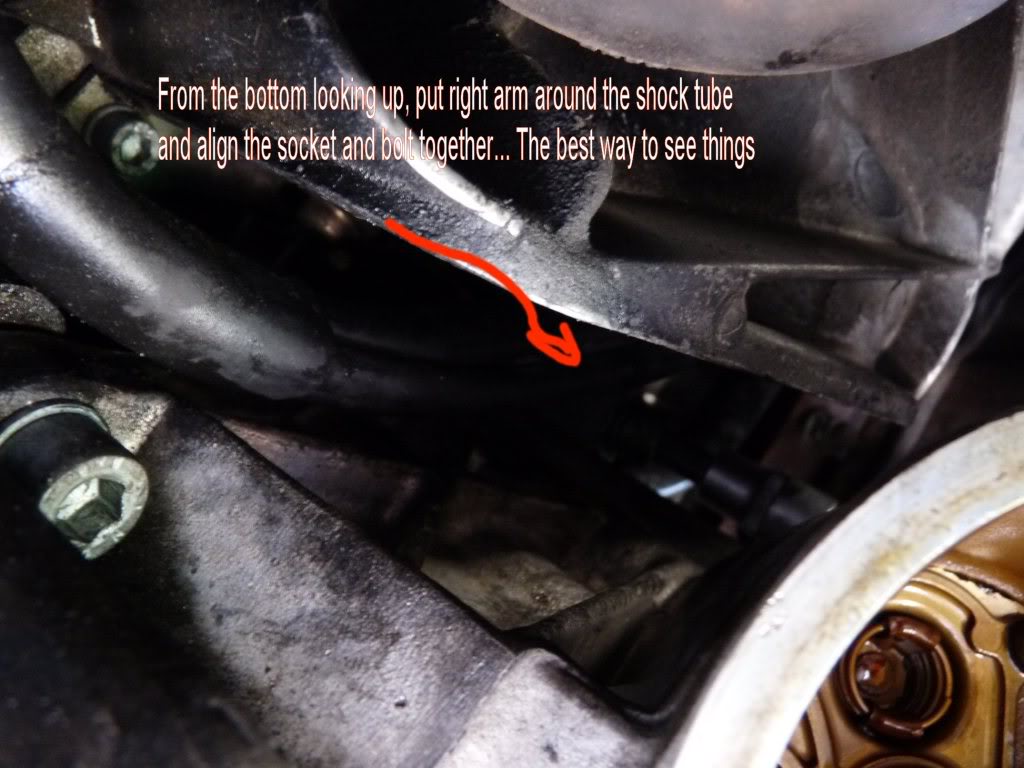

The oil cooler has 5 hex bolts. The hardest bolt is the top far left one looking from the passenger side of the car. Audipage.com recommended to raise the engine up, but we didn’t have to. The bolt is here. The best way to access this bolt is to lie under the car, put the arm around the bumper shock tube with extension and put the hex key in the bolt. When this one is out, the other 4 bolts are easy. The best way to access the hardest bolt is to use the extension like this

The hardest bolt with the extension in placed looking from the top of the car

To align the extension to the hardest hex bolt, we need to go under the car, put the arm around the bumper shock tube and push the hex key in the bolt, we should be able to see it very clearly from under the car providing it’s day light or with some lighting.

So, the oil cooler removal is only hard because of the position of the 1 bolt hiding behind the engine. All other bolts are in plain sight and easy to remove. Yes, we have to remove the oil filter, the alternator and yes, it’s best with the front end removed and the timing belt cover is out. The bottom line is when we replace the timing belt, water pump, do this oil cooler thing at the same time. Here is the $13 part that caused the whole mess.

There are total of 5 bolts to remove the oil cooler

There are 2 more bolt, 1 on the right lower on the picture above and one middle top just right of the oil filter housing.

When all 5 bolts are out, notice the short bolts (#3 under the oil filter, top middle right of the oil filter?) and all others should be long. Wiggle the oil cooler out from top and bottom and slide it out toward the front of the car to clear the black coolant metal pipe.

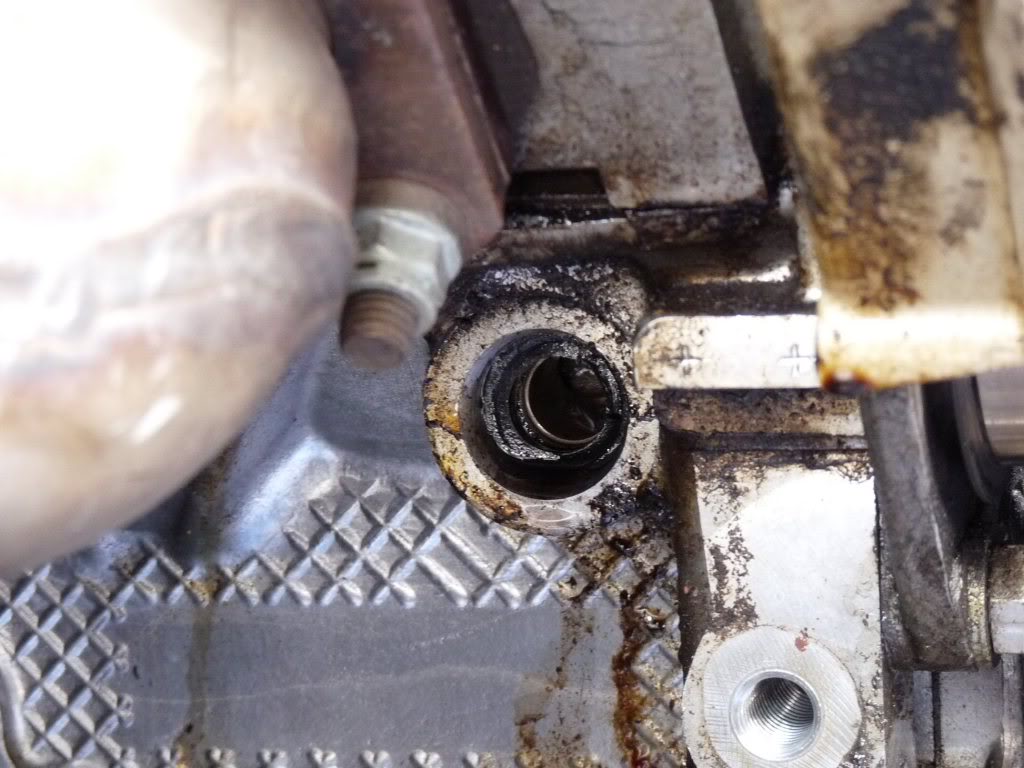

When the cooler is out, we will see the broken plastic pipe on the block and the cooler, we need to remove them to fit a new one.

Clean up the oil cooler and the block surfaces, fit new rings onto the new oil cooler pipe, new ring on the black metal pipe, “8” shape ring and rub some engine oil on them and the oil cooler is ready to be mounted back on. Make sure the aluminum guide cylinders are mounted.

We align the bottom cooler in first, align the hole with the metal pipe to fit it in second, slide it back while rotating the cooler to get it in (engine oil on the metal new ring will help sliding it in easily), next align the plastic pipe to the block, it’s visible from cooler, then slide it in the block hole, then everything will fit nicely (engine oil on the new rings will help sliding it in smoothly).

Tighten all the 5 bolts slowly and securely in diagonal fashion. Don’t forget the correct size of the bolts. Check out the 40V oil cooler for references

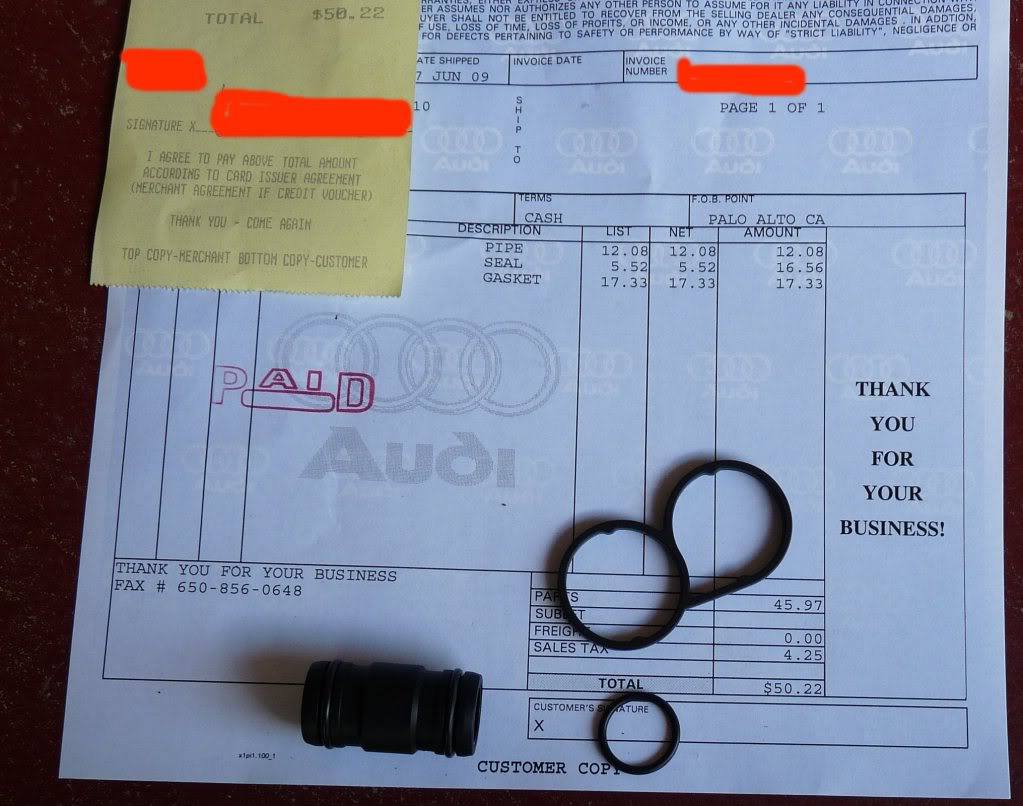

So the cost of the parts

Some dealers like Steven Creek Audi in San Jose did not sell us individual rings, only sell the whole set of rings for oil cooler which will replace all the rings in the cooler which we may not need. If the water doesn’t mix with oil in the engine, then we don’t need to replace all these. Most of the time, the rings are fine, the leaks are due to the broken brittle plastic pipe after over 100k miles with the engine over heated once or twice. Carlson Audi did sell us what we needed.

Cheers,

4 Comments

December 30, 2014.

First of all, thank you for your work in detailing and recording videos of this and many other procedures on your Audis. I’ve owned my 97 A8 4.2 for twelve years and have been through 170 of its 250k miles, which means a number of repair and maintenance projects with it.

I’m currently doing this oil cooler replacement. I’m ready to begin the re-assembly process and have a question. How do the small o-rings fit in the assembly on both the short water pipe (the plastic piece which is the cause of all this fun) and on the steel pipe towards the back of the oil cooler?

With the replacement water pipe, it is unclear to me if the o-rings should go on the *ends* of the replacement water pipe and therefore be pressed into the holes in the oil cooler and engine block, or if they should somehow be stretched onto/around the water pipe itself like a washer on a bolt, acting as a ring on a piston? I should mention that I’ve got the aluminum replacement water pipe, which already has double o-rings on each end of it. With this piece, do I even need the other o-rings? See why I’m confused?

The same question applies to the existing metal pipe towards the back of the oil cooler. Where should the o-ring go? Inside the oil cooler’s port for the pipe or around the pipe like a washer or ring on a piston?

It seems like a silly question, but it’s not something I want to mess up. Not with this much effort in the project. I’m going to head back to my garage and poke around a bit.

Thanks for any help you can provide, and keep enjoying your A8s.

Dennis

Hello Dennis,

Sorry for the late reply, we’re on New Year’s vacation. The original or after market rings are to be put outside on the grooves before pushing the pipe to the mating holes. There are 2 ways to do the pipe, one is to place the pipe all the way into oil cooler first, the other is to place the pipe all the way into the engine first. I think I put mine in the engine side first because I do have to wiggle the cooler and I didn’t want to break it by dropping the cooler by accident and hit something.

About the after market metal pipe with 2 rings. I believe Audi didn’t use the metal pipe is because of the heat dissipation. Plastic pipe may isolate heat between the coolant and the engine better than the metal. The only question I have for the metal is that the ring will be sandwiched between 2 hot metal (engine & the pipe) for a long period of time compared to engine and plastic, the rubber rings may get brittle faster with metal pipe compared to plastic pipe. All the leaks occur NOT due to broken plastic pipe, they leaked through the rings hence the leaks only exist after the pressure was in place (after engine stops and hot). When we removed the cooler, we yank it side way and the pipe was broken in the process due to force and degradation after many years. I rather to replace the original plastic pipe and original rubber ring knowing that the pair would last me 150k miles or more than using the metal pipe knowing nothing about the rings and the heat. My 150k miles car leaks due to driving at high speed with 1 quart low of oil on summer nights (90 degrees).

Cheers and good luck,

Louis